Completing the Well

A company will analyze and consider the data obtained from the various tests performed on the formation(s) of interest. From this analysis a decision is made whether to set production casing and complete the well or to plug the well and abandon it. What needs to be determined is the anticipated amount of oil and gas production should the well be completed. A producible well is one that can produce oil and/or gas in commercial quantities. A well that cannot produce oil nor gas in commercial quantities is considered to be dry. The primary consideration is if the well is anticipated to produce oil and/or gas in great enough quantities to justify the expense of completing and operating the well. The mere presence of oil and gas alone is not enough to justify completion, therefore a careful evaluation is required.

Dry wells that are abandoned do need to be plugged at the driller’s expense. A series of cement plugs needed to abandon a well may cost a few thousand dollars, however the cost of setting a production string of casing is usually $50,000 or more. The decision to complete or abandon a well is often difficult for the operator. Sometimes even abandoned wells will be reopened at a later time and produced if the price of oil or gas becomes more favorable.

Setting Production Casing

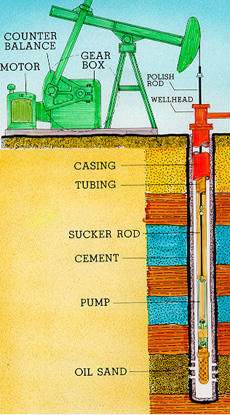

If the decision to open a well for productin is made casing will be brought to the well and the casing and cementing crew run and cement a string of casing. The hole is drilled to a depth beyond the producing formation and the casing is set to a point near the bottom of the hole. Production casing is set and cemented through the pay zone. This method results in the casing and cement sealing off the producing zone temporarily.

Cementing

After the casing string is run the casing is then cemented in place. The cementing is typically carried out by a cementing service company and usually the drilling rig crew will be on hand. The cementing service stocks a variety of cement and have the equipment necessary to transport and handle the material in large quantities. The cement

storage and handling equipment is moved to the rig allowing the cement to be mixed at the site of application. Dry cement is mixed with water in a device called a jet mixing hopper. Dry cement is slowly added to the hopper where a jet of water thoroughly mixes with the cement creating a slurry. Slurry is a very thin cement-water mix.

Slurry pumps pick up the cement and send it to a cementing head , which is a valve sometimes referred to as a plug container. The cementing head is mounted on the topmost casing joint which is hanging above the rig floor inside the derrick. Before the slurry arrives a rubber bottom plug is released from the cementing head and precedes the slurry down the inside of the casing. The bottom plug eventually seats in the float collar. Continued pressure applied to the slurry eventually pumps a hole through the bottom plug allowing the slurry to continue down the casing. The cement slurry then flows through an opening in the guide shoe and starts to fill up the annular space between the outside of the casing and the bore wall. Pumping continues until the cement fills the annular space which will eventually brace the tubing solidly in place.

Later a top plug which is similar to the bottom plug, only solid is dropped into place as the last of the slurry enters the casing. Following the top plug displacement fluid such as salt water or drilling mud is pumped in. As the top plug is pushed toward it’s destination most of the cement slurry flows out of the casing and fills the annular space. When the top plug seats on or “bumps” the bottom plug in the float collar it is time for the cementing pump operator to shut down the pumps. At this point the cement occupies only the casing below the float collar and the annular space. The casing above the float collar is filled with displacement fluid.

Time is needed for the cement slurry to harden. This waiting period is called waiting on cement or the initials WOC.

After WOC tests may be conducted to ensure a good cement job. Cement supports the casing so it should surround the casing completely. Centralizers on the casing can help. If casing is centered in the bore hole a cement sheath is formed. In addition to supporting the casing, cement prevents fluids from formations migrating to other formations above or below them. In this way the cement can protect freshwater formations which may be used as a municipal water supply from saltwater contamination. Cement also protects the casing from the corrosive effects of fluids such as saltwater in the surrounding formations.